Modular fence systems solve common fencing challenges like warping, rotting, and difficult installations on slopes. They use durable steel frameworks, offer design flexibility with various infill materials, and simplify installation with pre-engineered components. FenceTrac‘s system, for example, features an 18-gauge galvanized steel frame with a powder-coated finish, accommodating infill materials up to 1 inch thick. It’s designed to handle slopes up to a 45% grade and withstand wind speeds of up to 150 mph.

Key Benefits:

- Durability: Steel framework resists rot, warping, and pests, lasting over 20 years.

- Flexibility: Compatible with wood, composite, metal, PVC, bamboo, and more.

- Ease of Installation: Pre-fabricated components reduce labor and time.

- Low Maintenance: Powder-coated finish eliminates the need for regular upkeep.

- Customization: Available in various colors, infill options, and layouts.

FenceTrac’s system also includes detailed CAD drawings and specifications, making it easy to integrate into architectural plans. This modern solution combines strength, design options, and simplified assembly, addressing the needs of both residential and commercial projects.

How to Build a Modular Fence

sbb-itb-908b3eb

FenceTrac Modular Fence System Overview

The FenceTrac system stands out with its patented U-channel steel frame, which securely encloses infill materials. This design creates a sturdy, warp-free panel, addressing common issues like sagging and twisting that traditional wood fences often face. The framework is crafted from 18-gauge roll-formed galvanized steel, boasting a minimum yield strength of 45,000 psi.

Each steel component undergoes a hot-dip galvanization process, ensuring a zinc coating weight of 0.90 oz per square foot (Coating Designation G-90). Afterward, a textured TGIC polyester powder coat finish is applied at a minimum thickness of 3 mils, providing exceptional durability. This finish has been tested to withstand over 1,000 hours of salt-spray exposure, meeting ASTM B117 standards.

“It uses steel posts instead of wood that can rot and decay. It also has a steel frame, so you don’t see warping or twisting that you would usually see in a typical wood fence.” – Joe Everest, Owner, Ozark Fence

The system supports a wide range of rigid infill materials up to 1 inch thick. Options include Western Red Cedar, LuxeCore composite, UltraBlend PVC, corrugated metal, welded wire mesh, bamboo, Hardie board, and even stone or brick veneer panels. The standard frame color is Black, but White, Silver, and Bronze are available as alternatives.

The sections below explore the system’s features, technical details, and installation process.

FenceTrac System Features

FenceTrac’s assembly is straightforward, featuring a metal-on-metal design with a 4-bolt panel system and self-tapping screws for attaching to posts – no welding or nails required. The posts are made from 12-gauge or 14-gauge galvanized steel (G-60) and are designed to last for decades, far outliving traditional wood posts.

The rackable framework is engineered to handle slopes up to a 45% grade without custom fabrication, ensuring a smooth, continuous top line. Additionally, the system is rated to withstand wind speeds of up to 150 mph, meeting ASCE 7-05 standards and making it ideal for commercial and industrial applications in high-wind areas.

Unlike conventional fences that have a distinct “good” and “bad” side, FenceTrac offers a uniform look on both sides. This is achieved by concealing all anchoring points within the U-channel design.

| Component | Material Specification | Gauge/Thickness | Yield Strength |

|---|---|---|---|

| Framework (Trac) | Galvanized Steel (G-90) | 18 Ga. | 45,000 psi |

| Posts | Galvanized Steel (G-60) | 12 Ga. or 14 Ga. | 45,000 psi |

| Finish | TGIC Polyester Powder Coat | 3 mils (min) | N/A |

| Infill Capacity | Various (Wood, PVC, etc.) | Up to 1″ thick | N/A |

Benefits of Modular Construction

The modular design simplifies specifications for architects. Instead of detailing every board and fastener, you can specify a standardized steel framework and pair it with the desired infill material. This streamlined process reduces the likelihood of errors during construction.

Installation is faster compared to traditional fence building. Each four-piece panel assembles with just four bolts, saving labor hours and speeding up project timelines. Pre-fabricated parts arrive ready for assembly, eliminating the need for on-site measuring, cutting, or fastening.

“The thing I like the most is that you can choose whatever material you’d like to fill the frame. Whatever is good for your style or home, FenceTrac allows us to find something to fit it.” – Joe Everest, Owner, Ozark Fence

The system also offers flexibility for future updates, including options for semi-privacy fencing. Property owners can easily swap or upgrade infill panels without dismantling the steel framework. This feature is especially useful for adapting to changing tastes or updating branding in commercial spaces.

When paired with PVC or composite infill, maintenance becomes minimal – no painting, staining, or sealing is required. The powder-coated frame resists issues like rot, warping, and pest damage. This adaptability makes FenceTrac an appealing option for those seeking a durable and versatile fencing solution.

For more detailed technical drawings and specifications, visit the Architects Specifications & Drawings page.

FenceTrac vs. Custom-Built Fencing

When comparing FenceTrac modular systems to traditional wood fences, the differences in durability and overall ownership costs stand out. Traditional wood fences often face issues like rot, warping, and pest damage over time. In contrast, FenceTrac uses an 18-gauge galvanized steel framework that eliminates these problems entirely. This structural solution not only lasts for decades but also avoids the recurring expenses tied to wood repairs and replacements. Here’s how FenceTrac delivers better longevity and simplifies installation.

Durability and Long-Term Costs

FenceTrac’s steel framework is built to withstand environmental stress that typically weakens wood fences. While wood posts often need replacing after 10-15 years due to ground-level rot, FenceTrac’s galvanized steel posts (G-60 coating) and 18-gauge framework (G-90 coating) are designed to last more than 20 years with minimal maintenance. Its powder-coated finish, tested to endure over 1,000 hours of salt-spray exposure (per ASTM B117 standards), provides exceptional corrosion resistance compared to painted or stained wood.

| Feature | FenceTrac Modular System | Traditional Custom Wood Fence |

|---|---|---|

| Framework Material | 18-ga Galvanized Steel | Traditional wood (requires regular care) |

| Finish | TGIC Powder Coat (3 mils) | Paint or Stain (needs frequent reapplication) |

| Maintenance Needs | Low to None | High (staining/sealing every 2-3 years) |

| Common Issues | None (resists rot and pests) | Rot, warping, sagging, leaning |

| Lifespan | 20+ Years (structural) | 10-15 Years (variable, prone to rot) |

| Warranty | 20-Year Limited Warranty | Typically No Warranty |

When paired with composite or PVC infill, FenceTrac requires virtually no upkeep – no staining, painting, or sealing. While cedar wood infill offers lower upfront costs, it demands ongoing care and lacks a warranty. By contrast, LuxeCore composite and UltraBlend PVC infills earn top marks for durability and are backed by limited lifetime warranties, surpassing anything traditional wood can offer. This durability also simplifies installation, as detailed below.

Installation Time and Complexity

Custom wood fencing often involves labor-intensive processes like measuring, cutting, and fastening individual boards on-site. FenceTrac eliminates these steps with pre-fabricated components that are ready for assembly. Each panel consists of four pieces that connect using just four bolts, while side channels attach to posts with self-tapping screws – no welding, no specialized tools, and no tedious board alignment required.

The system’s rackable design adjusts to slopes up to a 45% grade without needing custom fabrication, avoiding the stepped cuts and adjustments that traditional fences require on uneven ground. Infill materials slide easily into U-shaped channels, skipping the time-consuming task of fastening individual pickets. This streamlined process significantly reduces installation time, cutting labor costs and helping architects meet tight deadlines more efficiently.

Technical Specifications for Architects

These specifications provide architects with the exact dimensions and material details needed for seamless integration into their projects.

Standard panels feature an 18-gauge galvanized steel framework, designed for durability and consistent performance. The framework accommodates rigid infill up to 1 inch thick and is available in panel widths of 6 feet (72″) and 8 feet (96″), with heights of 4, 6, or 8 feet. For proper assembly, ensure total post clearances of 72¼ inches (6-foot panels) or 96¼ inches (8-foot panels).

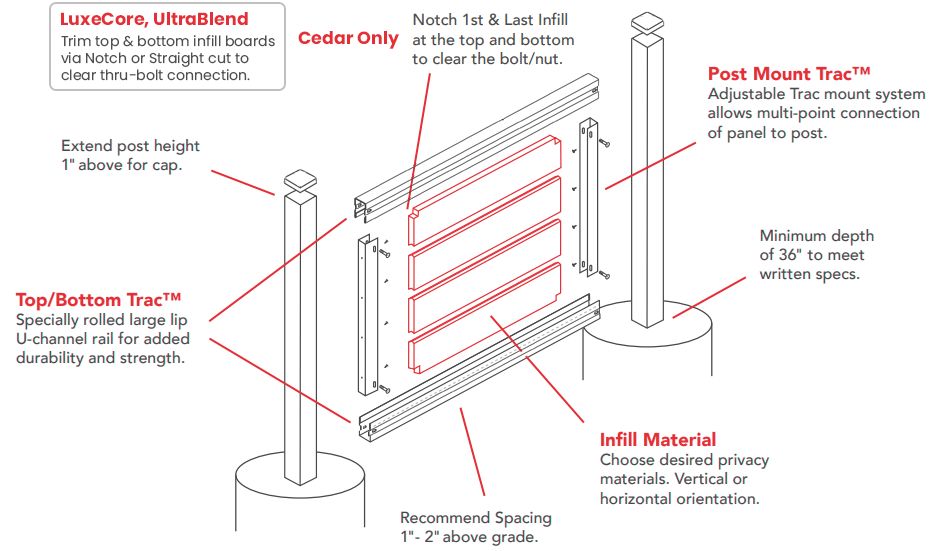

Metal components are coated with a thermosetting Polyester-TGIC powder finish, tested according to ASTM B117 standards. Posts come in sizes ranging from 2.5″ x 2.5″ to 4″ x 4″, constructed from 12- to 14-gauge steel, and must be set in concrete footers at least 36 inches deep, or deeper if local frost-protection codes require it.

Privacy Fence Systems

FenceTrac privacy systems are designed to meet both residential and commercial needs, with heights of 4, 6, or 8 feet. The rackable framework adjusts to slopes up to a 45% grade, measured along the slope rather than horizontally. Gates are available in widths ranging from 48 to 72 inches, built with extruded aluminum frames and equipped with commercial-grade hinges capable of supporting up to 600 pounds. The steel framework is backed by a 20-year limited warranty, while premium infill options, including LuxeCore composite and UltraBlend PVC, come with a 20-year structural guarantee. These precise specifications ensure reliable performance across a variety of applications.

Materials and Finishes

Material and finish options allow architects to customize the FenceTrac system to their design goals. LuxeCore composite boards measure 1″ x 5.875″ and are available in 6-foot lengths, with color options including Black Onyx, Harbor Gray, Timber Brown, and Tropical Teak. UltraBlend PVC infill shares the same dimensions and comes in finishes such as Aged Cedar, Natural Cedar, Chestnut Brown, and Redwood. For natural wood, Western Red Cedar is offered at 0.875″ x 5.5″ in lengths of 6 or 8 feet, but installation requires notching the first and last boards (between 1-1/2″ x 1-1/2″ and 3″ x 3″) to clear bolt connections during assembly. For fire-rated applications, 6063-T5 aluminum infill meets ASTM E84-24 Class A standards.

The steel framework is available in Black (standard stock color), White, Silver, and Bronze, with additional custom colors available upon request.

For detailed technical drawings and specifications, visit the Architects Specifications & Drawings page.

Design and Customization Options

The FenceTrac system gives architects the freedom to explore various infill orientations and materials, making it a versatile choice for different design needs. Panels can be arranged in horizontal or vertical layouts. Horizontal patterns create a sleek, modern look that can make smaller spaces feel larger, while vertical layouts offer a more classic, traditional style. The system’s U-channel design accommodates infill materials up to 1 inch thick, opening up a wide range of possibilities.

Beyond layout flexibility, the choice of materials adds another layer of design potential. Options include:

- Natural wood: Western red cedar, Eastern red cedar, cypress, ipe, and even reclaimed barn wood.

- Synthetic composites: LuxeCore with a cellular PVC core and ASA casing, or UltraBlend PVC featuring wood-grain textures.

- Metal panels: Corrugated, ribbed, perforated, etched, or aluminum slats.

- Specialty materials: Bamboo, stone or brick veneer, Hardie board, and welded wire.

“The thing I like the most is that you can choose whatever material you’d like to fill the frame. Whatever is good for your style or home, FenceTrac allows us to find something to fit it.” – Joe Everest, Owner, Ozark Fence

Privacy levels can also be tailored to specific needs. Tongue-and-groove boards provide complete privacy, while spaced slats allow airflow and light to pass through, creating a semi-private effect. For vertical infill designs, the Vertical H-Trac component ensures added mid-panel support for a polished and sturdy look.

Frame colors include standard options like Black, White, Silver, and Bronze, but custom colors can also be requested. All frames are coated with a textured TGIC polyester powder finish, tested to withstand corrosion for at least 1,000 hours under ASTM B117 standards. Gates are designed to match seamlessly, whether for walk-through or drive-through configurations, ensuring a cohesive appearance.

For projects requiring fire-rated materials, aluminum infill options are available to meet safety standards.

The system’s rackable design ensures clean, straight lines even on slopes up to a 45% grade. These features combine to offer architects a solution that balances aesthetics with functionality, simplifying the design process while delivering high-quality results.

Installation and Assembly Process

The installation process for the FenceTrac system is designed to be quick and straightforward, eliminating unnecessary complications. With no welding required and only a few basic tools needed – like a power drill, post-hole digger, level, measuring tape, and concrete mixer – contractors can easily handle the setup. Its modular design also removes the hassle of on-site cutting and measuring that’s often part of traditional fencing projects.

Start by setting steel posts into concrete footers that are at least 36 inches deep, or deeper if required by local codes. On sloped terrain, measure post spacing along the actual grade to accommodate the system’s rackable framework, which can adjust to slopes of up to 45%. Once the posts and channels are firmly in place, move on to installing the infill. Attach the pre-drilled Post Tracs to each post using self-tapping screws. Thanks to the slotted mounting holes, you can make precise adjustments during alignment.

Next, slide the infill panels – up to 1 inch thick – into the patented U-channels. These channels hold the panels securely without the need for individual fasteners. Then, attach the Top and Bottom Tracs to complete the frame, securing the panel with just four bolts.

“Side channels bolt to each post with self-tapping screws… Each four-piece panel assembles with just four bolts.” – FenceTrac

Because the components are pre-engineered 6-foot fence kits and pre-cut components, there’s no need for on-site fabrication. This mechanical assembly process makes it possible for general contractors or small crews to finish installations efficiently, saving both time and money. FenceTrac’s streamlined approach to assembly is not only practical but also helps reduce labor costs and installation time.

Specifications and Drawings Resources

Architects require dependable technical documentation to accurately include FenceTrac systems in their project plans. The FenceTrac Specifications & Drawings page acts as a go-to resource, offering downloadable CAD drawings, CSI MasterFormat specifications, and performance data sheets. These materials work hand-in-hand with the system’s straightforward design and installation process, providing everything needed to seamlessly incorporate FenceTrac into project plans.

The page includes CAD files in multiple formats – PDF, DWG, DXF, and STEP – covering privacy fences, semi-privacy designs, and gate layouts in 4-, 6-, and 8-foot heights. For those using BIM workflows, Revit and SketchUp models are available via CADdetails.com, allowing for smooth integration into site plans and elevations. Additionally, CSI MasterFormat specifications (Section 32 31 00, “Fences and Gates – Customizable Privacy Metal Fence System”) can be downloaded from ARCAT.com in Word, RTF, and text formats, ensuring compliance with industry standards for project manuals.

Performance data sheets offer a concise overview of key metrics, including wind load test results that meet ASCE 7-05 standards, along with accessible 20-year warranty documentation for client presentations. These resources consolidate critical performance details, making it easier for architects to finalize their designs with confidence.

To further support this, a demonstration video highlights FenceTrac’s modular system and its ease of on-site assembly. The video, embedded below, showcases how the four-bolt panel system is constructed using Post Tracs, U-channels, and infill materials:

<iframe width=”560″ height=”315″ src=”https://www.youtube.com/embed/yKQT1rjEj7Q” frameborder=”0″ allow=”accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture” allowfullscreen></iframe>

This visual guide demonstrates how the patented U-channels accommodate infill materials up to 1 inch thick and how slotted mounting holes provide flexibility during installation. By complementing the technical drawings, the video helps architects grasp the mechanical assembly of the system without requiring welding or specialized fabrication.

Conclusion

FenceTrac modular fence systems tackle many of the challenges architects encounter when selecting perimeter fencing for both commercial and residential projects. The 18-gauge galvanized steel framework with its patented U-channel design supports a wide range of rigid infill materials up to 1 inch thick, including wood, composite, metal, PVC, bamboo, and even glass. This approach combines durability with unmatched design flexibility, eliminating the usual trade-offs between function and appearance.

On top of its durability, FenceTrac simplifies installation. With 4-bolt panel assembly and pre-drilled components, the system eliminates the need for welding or custom fabrication, saving time and effort on-site. Its rackable framework adjusts to slopes of up to a 45 percent grade, avoiding the stepped appearance and tedious cutting often required on uneven terrain. For architects working under tight deadlines, these features mean quicker installations and fewer follow-ups.

The modular design also makes long-term maintenance and updates a breeze. individual infill panels can be swapped out or upgraded without disassembling the entire structure. Add to that a 20-year structural warranty and powder-coated finishes that withstand 1,000 hours of corrosion testing, and the result is a fence system that offers a lower total cost of ownership over time, even if the upfront costs are higher.

For architects who need detailed documentation, the Specifications & Drawings page offers downloadable CAD files, CSI MasterFormat specifications (Section 32 31 00), and performance data sheets. These resources integrate seamlessly into project manuals and BIM workflows, making it easier to specify FenceTrac for both demanding commercial projects and upscale residential developments.

FAQs

How do I specify FenceTrac in my project documents?

To add FenceTrac to your project documents, make sure to reference the detailed specifications and drawings available on the FenceTrac website. These resources outline everything you need to know about the system’s components, materials, and installation instructions.

When specifying FenceTrac, include its patented U-channel rails, modular panels, and hardware to ensure everything is clear and precise. It’s also a good idea to provide the manufacturer’s contact details and website. This helps contractors easily access the official documentation, ensuring proper installation and meeting material requirements.

Will FenceTrac work on sloped sites?

FenceTrac works well on sloped sites without needing stepped panels. Its design allows it to adjust to ground grade variations, creating a smooth and even fence line.

Which infill materials are best for my project?

Choosing the right infill material for your FenceTrac system comes down to what matters most to you – whether that’s privacy, durability, low maintenance, or style. For those who want maximum privacy with little upkeep, solid materials like composite or PVC are excellent choices. On the other hand, if you’re aiming for a semi-private or more open design, aluminum pickets or wire mesh can provide the perfect balance. Thanks to FenceTrac’s modular design, you have the freedom to customize with nearly any material to fit your specific project needs.