Specifications & Drawings

Color options include: white, bronze, silver, or custom color.

SPECIFICATIONS & DRAWINGS

Specifications & Drawings

To create an entire fence system, you generally need the following four components: Frame Kits – Posts – Infill – Gate(s). Browse specs below to plan your project. When you’re ready, submit a quote request for detailed pricing. Standard FenceTrac color is black. Color options include: white, bronze, silver, or custom color. Ask for details.

Kits

System

Features

Drawings

CSI Specs

FENCE SYSTEM KITS

FenceTrac Privacy

Learn More »

Ultrablend PVC

Learn More »

LuxeCore Composite

Learn More »

Highplains Rail

Learn More »

FenceTrac Enclosures

Learn More »

OmniView Welded Wire

Learn More »

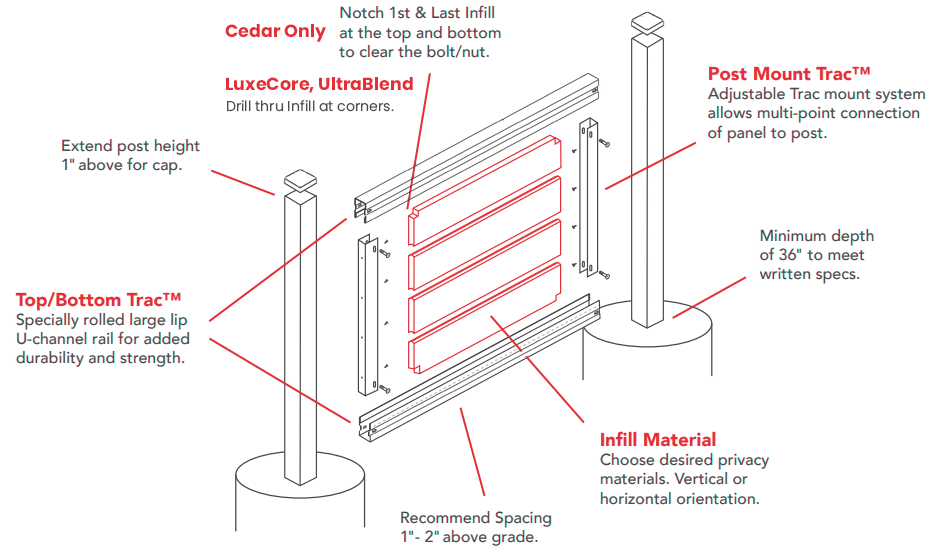

EXPLODED VIEW

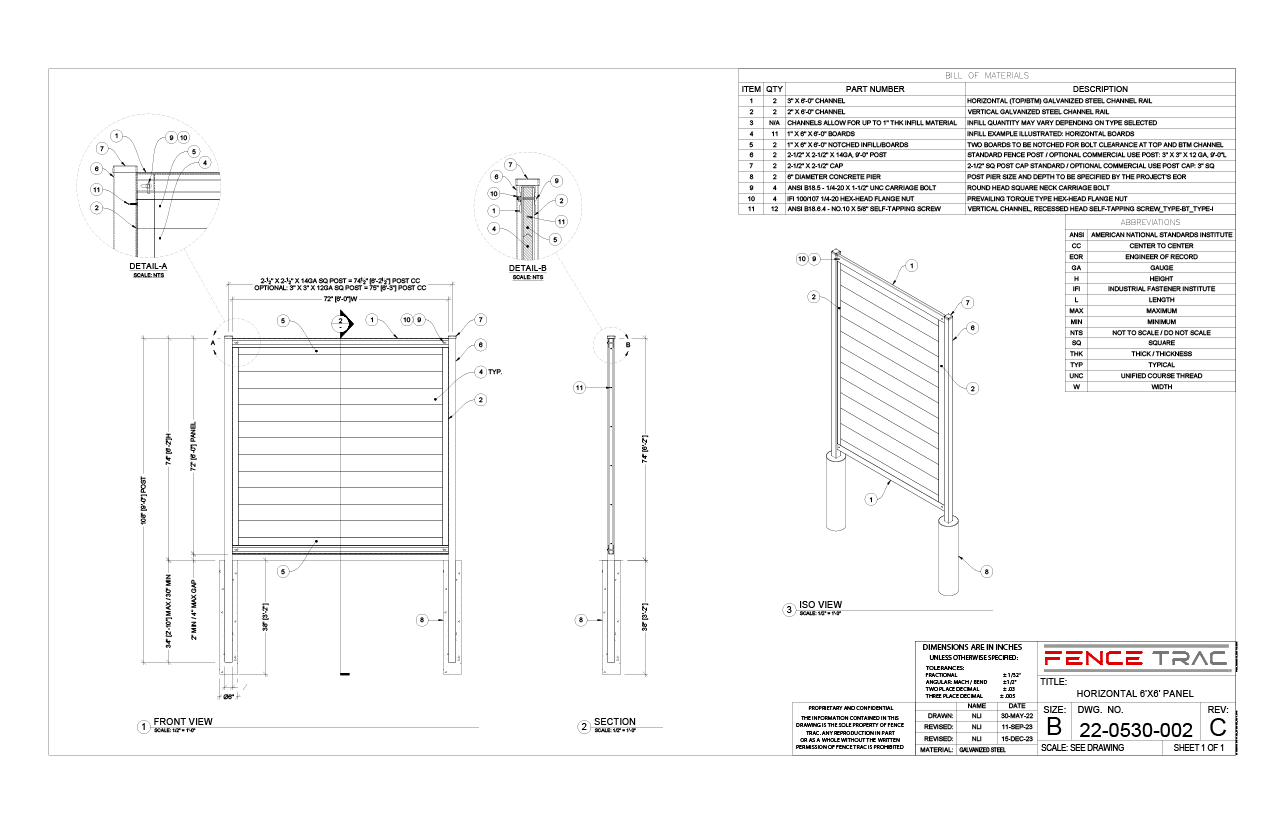

The FenceTrac fence system is a modular fence kit designed to build fences in 4-foot, 6-foot or 8-foot heights. The standard FenceTrac fence panel kit includes: (1) Top Trac, (1) Bottom Trac, (2) Post Tracs (for post mount) and hardware to assemble metal components. Panel width is 6-foot or 8-foot.

Patented FenceTrac U-channels are manufactured from galvanized 18 ga. steel for superior strength and durability. Mounting points include slotted holes for flexible installation tolerances. All metal components are powder coated for durability. Here’s a look at how each panel goes together.

WHY BUY FENCETRAC

A Better Fence System

- Modern look for residential or commercial property

- Pair with any infill to create the design you want

- Accommodates infill thickness up to 1″

- Rackable framework for fencing sloped grades

- Lower lifetime cost than cheaper fence systems

- Metal frame creates a stronger, longer-lasting fence

- Fast, same-day quotes for most projects

- Crated for protection, shipped with quality carriers

Construction Features

- Heavy commercial grade design & manufacturing

- Trac channels 18-ga roll-formed galvanized steel

- Standard gates are extruded aluminum

- Textured TGIC polyester powder coat “baked on” finish

- 4-Bolt panel assembly (self-tapping screws for posts)

- Slotted holes for field tolerance & faster assembly

- Assembly hardware included, no welding required

- Wide custom-welded gates & enclosures available

Project Photos

DRAWINGS & DOWNLOADS

Download CAD Drawings

Other Resources

FenceTrac Frame Kits

| Item | Fence Height | Infill Direction | Item Number |

|---|---|---|---|

| 4'H x 6'W Frame Kit | 4-Foot | Vertical or Horizontal | 4X6FRBLK |

| 4'H x 8'W Frame Kit | 4-Foot | Vertical | 4X8FRBLK |

| 6'H x 6'W Frame Kit | 6-Foot | Vertical or Horizontal | 6X6FRBLK |

| 6'H x 8'W Frame Kit | 6-Foot | Vertical | 6X8FRBLK |

| 8'H x 6'W Frame Kit | 8-Foot | Vertical or Horizontal | 8X6FRBLK |

Steel Fence Posts

| Item | Fence Height | Description | Item Number |

|---|---|---|---|

| 2.5" x 2.5" x 7'L Post | 4-Foot | Painted Post w/Cap | P25084BLK |

| 2.5" x 2.5" x 9'L Post | 6-Foot | Painted Post w/Cap | P25108BLK |

| 3.0" x 3.0" x 9'L Post | 6-Foot | Painted Post w/Cap | P30108BLK |

| 2.5" x 2.5" x 12'L Post | 8-Foot | Painted Post w/Cap | P25144BLK |

| 3.0" x 3.0" x 12'L Post | 8-Foot | Painted Post w/Cap | P30144BLK |

Infill Options

FenceTrac offers certain standard infill materials for use in our kits.

| Item | Description | Colors |

|---|---|---|

| 6-Foot Composite Picket | 1" x 5.875" Tongue & Groove | Black Onyx, Harbor Gray, Timber Brown, Tropical Teak |

| 6-Foot Cedar Picket | 0.875" x 5.5" Tongue & Groove | Natural |

| 8-Foot Cedar Picket | 0.875" x 5.5" Tongue & Groove | Natural |

| 6-Foot Vinyl Picket | 0.875" x 11.3" Tongue & Groove | Aged Cedar, Natural Cedar, Chestnut Brown, Redwood, Weathered Cedar & More |

| 8-Foot Vinyl Picket | 0.875" x 11.3" Tongue & Groove | Aged Cedar, Natural Cedar, Chestnut Brown, Redwood, Weathered Cedar & More |

Customer-supplied infill offers unlimited fence design possibilities. FenceTrac works great paired with: corrugated metal, welded wire mesh, metal screen, composite boards, bamboo, hardie board, metal slats, wood slats, vinyl or nearly any other rigid material under 1″ thick.

Gates & Hardware

| Item | Gate Height | Description | Item Number |

|---|---|---|---|

| 4'H x 48"W Walk-through Gate | 4-Foot | 48" Wide | G4X48BLK |

| 4'H x 72"W Walk-through Gate | 4-Foot | 72" Wide | G4X72BLK |

| 6'H x 48"W Walk-through Gate | 6-Foot | 48" Wide | G6X48BLK |

| 6'H x 72"W Walk-through Gate | 6-Foot | 72" Wide | G6X72BLK |

| 8'H x 48"W Walk-through Gate | 8-Foot | 48" Wide | G8X48BLK |

| 8'H x 72"W Walk-through Gate | 8-Foot | 72" Wide | G8X72BLK |

| Residential Hinge Set | Includes (2) Hinges | KMS-20-IHB | |

| Commercial Hinge Set | Includes (2) Hinges | KMS-HDEMBCHS | |

| Residential Latch | Lockable Gate Latch | KSS-DUAL | |

| Heavy-duty Drop Rod | 1" x 48"L | KMS-HDEMBDR |